Piping Stress Analysis

The use of finite element software allows to solve a wide range of problems inherent the design of pressure components, otherwise not solvable except with large margins of oversizing.

The use of finite element software allows to solve a wide range of problems inherent the design of pressure components, otherwise not solvable except with large margins of oversizing.

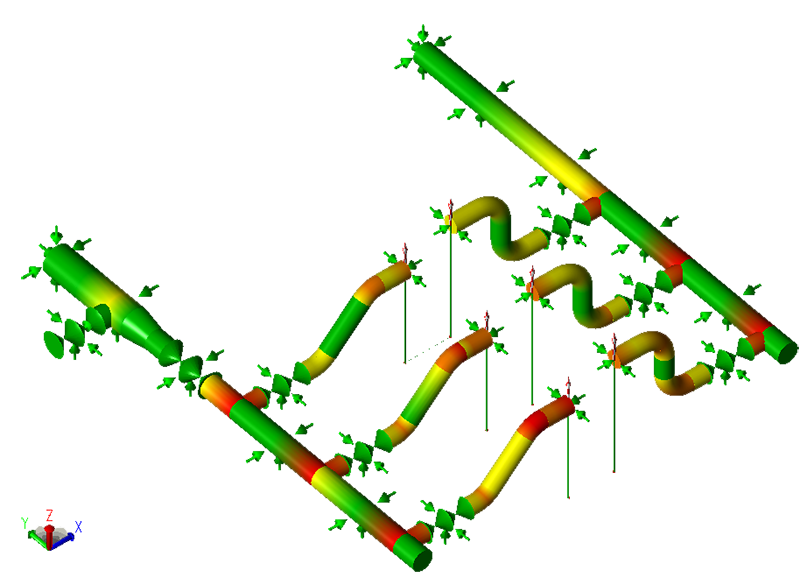

VCE Engineering offers an engineering service that uses finite element analysis for the stress analysis of a plant’s piping, the analysis of details of pipes themselves or pressure equipment (racks, nozzles, supports), or for the evaluation of an entire system.

Among the most widely used international standards, in addition to specific customer standards, we mention:

Analytical checks are carried out using specific softwares such as CAESAR II.

The specialization provided for this discipline include, in addition to the above, the design of supports and structural elements necessary for supporting pipes and equipment is also included.

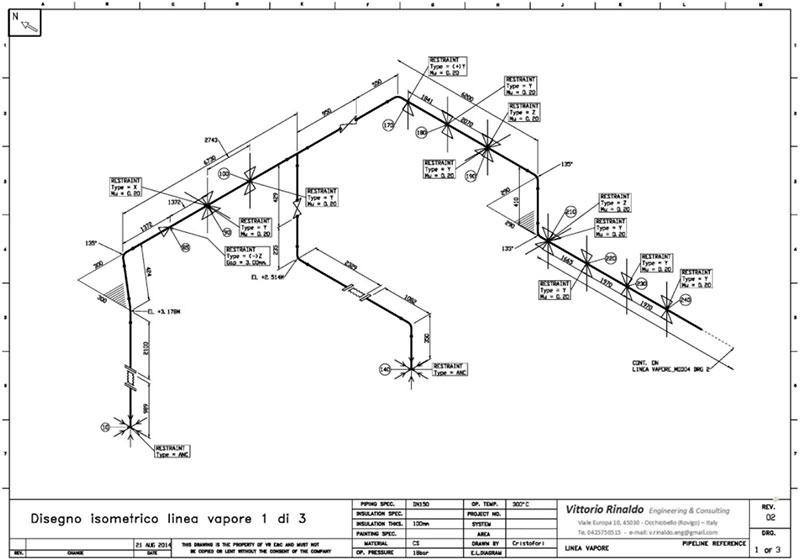

The analysis reports may be completed with isometric stress drawings, drawing up construction drawings and carrying out the structural checks necessary for the proper installation and proper operation of the plant.

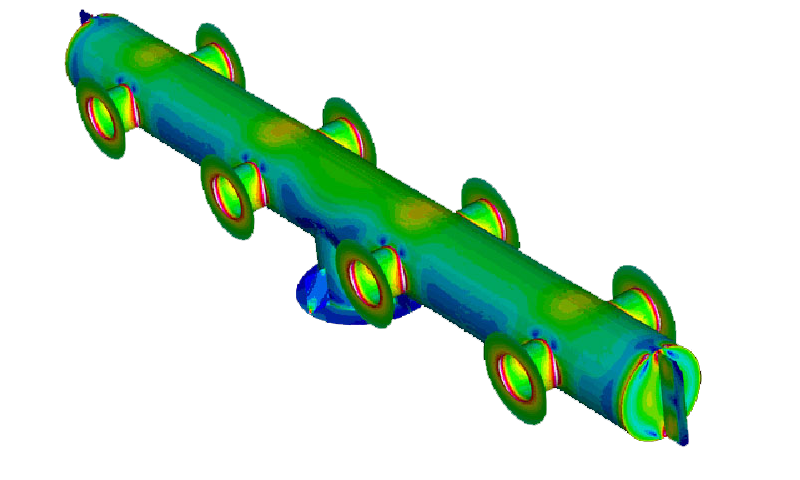

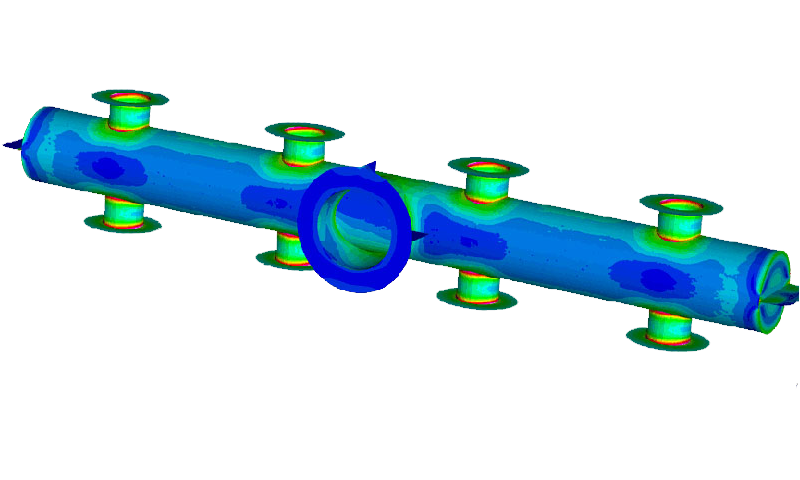

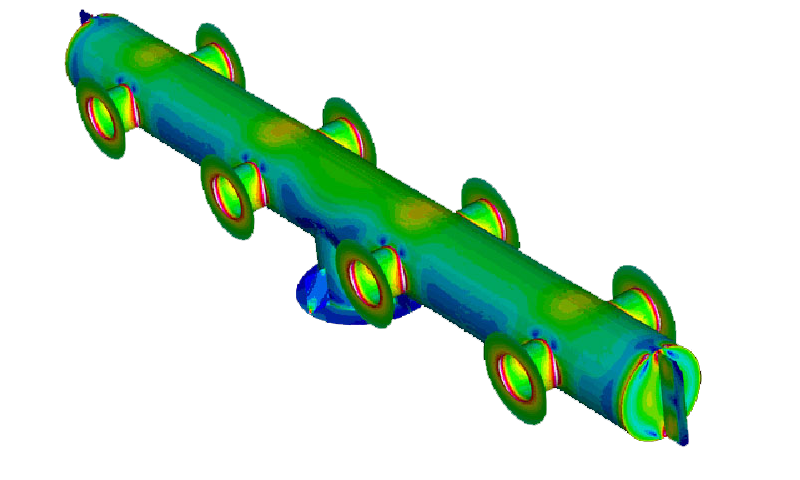

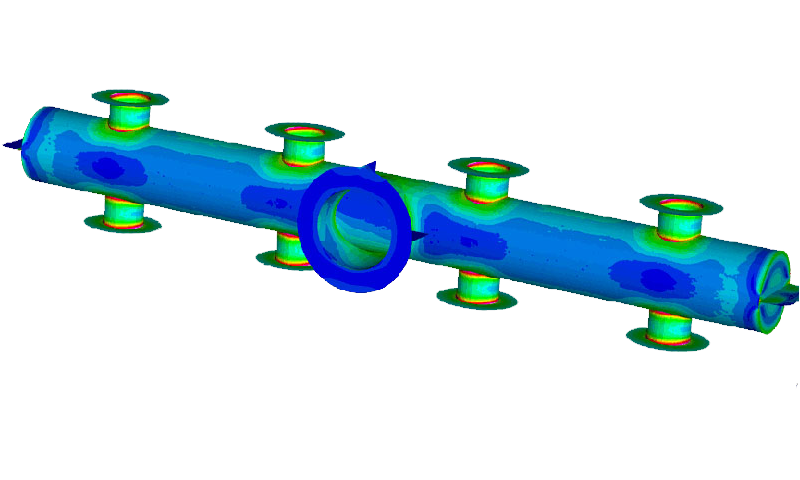

Whenever the design by formula fails to simulate adequately the geometry of a pressure-sensitive equipment, or if you want to optimize the design of it or a part of it, you can use the finite element method.

The performance and results of the analysis for pressure equipment follow the requirements of ASME BPVC Scet.VIII div. Part 5 or EN 13445-3.

The analyses, linear or non-linear, can be performed using 3-D elements or shell elements, also with software dedicated to the analysis of pressure parts, such as NozzlePRO.

By using FEA, typically with 3-D axisymmetric models, thermal and structural studies on the Hot-Boxes are also performed as per ASME VIII div. 2.